Super Swivels

Male Pipe (N.P.T.F.) X Female Pipe (N.P.T.F.)

Vendor: Super Swivels

Coupling Type: Hydraulic Couplings & Adapters

Coupling Category:

90° Dual Plane Swivels

Super Swivels® are manufactured from Carbon Steel or 304 and 440c Stainless Steel and offered with a wide variety of seal options.

Super Swivels are used in a wide variety of applications, i.e. hose reels, hydraulic log loaders, paint equipment, automatic car washes, wrecker trucks, horizontal directional drilling, machine tool indexers, hydraulic wheel motors, hot tar applicators, robotics, power line equipment, railroad equipment, and mining equipment, to mention a few.

Super Swivels are manufactured from Carbon Steel or 304 and 440c Stainless Steel.

304 Stainless Steel (304) is recommended for low pressure corrosive environments.

440c Stainless Steel (SS) is a martensitic, high carbon, magnetic stainless steel, heat-treated to maintain a high-pressure rating. Not as corrosion resistant as 300 Series Stainless Steel.

All stainless steel swivels have a 4 to 1 proof pressure.

(AL) Aflas® (Tetrafluoroethylene-propylene copolymer)

Super Swivels are used in a wide variety of applications, i.e. hose reels, hydraulic log loaders, paint equipment, automatic car washes, wrecker trucks, horizontal directional drilling, machine tool indexers, hydraulic wheel motors, hot tar applicators, robotics, power line equipment, railroad equipment, and mining equipment, to mention a few.

Options

Base Material

Super Swivels are manufactured from Carbon Steel or 304 and 440c Stainless Steel.

304 Stainless Steel (304) is recommended for low pressure corrosive environments.

440c Stainless Steel (SS) is a martensitic, high carbon, magnetic stainless steel, heat-treated to maintain a high-pressure rating. Not as corrosion resistant as 300 Series Stainless Steel.

All stainless steel swivels have a 4 to 1 proof pressure.

Seal Material

(V) Viton® (Fluorocarbon) – For most petroleum based applications. (-15°F to 250°F)(AL) Aflas® (Tetrafluoroethylene-propylene copolymer)

- Better resistance to many individual chemicals.

- For service in high temperature environments.

- (Low temperature limitations.)

- ( 32°F to 400°F)

- Buna

- EPR

- Neoprene

- Kalrez®

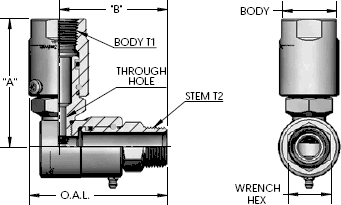

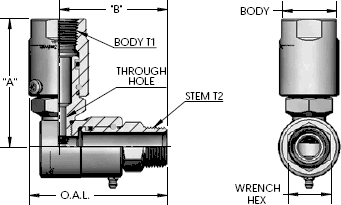

| PART NUMBER | O.A.L. | DIM. B | BODY | WRENCH/ HEX |

BODY T1 N.P.T.F. |

STEM T2 N.P.T.F. |

DIM. A | MAX. P.S.I.G. |

THROUGH HOLE |

| 9 DP 4 MP 25 X FP 25 | 2.640 | 2.130 | 0.875 | 0.625 | 1/4-18 | 1/4-18 | 2.689 | 5000 | 0.250 |

| 9 DP 8 MP 38 X FP 38 | 3.193 | 2.548 | 1.125 | 1.000 | 3/8-18 | 3/8-18 | 3.063 | 5000 | 0.297 |

| 9 DP 8 MP 50 X FP 50 | 3.318 | 2.673 | 1.250 | 1.000 | 1/2-14 | 1/2-14 | 3.053 | 5000 | 0.297 |

| 9 DP 12 MP 75 X FP 75 | 3.598 | 2.760 | 1.500 | 1.125 | 3/4-14 | 3/4-14 | 3.190 | 4500 | 0.391 |

| 9 DP 16 MP 100 X FP 100 | 4.420 | 3.462 | 1.750 | 1.375 | 1-11 1/2 | 1-11 1/2 | 4.090 | 4000 | 0.484 |

| 9 DP 20 MP 125 X FP 125 | 4.973 | 3.795 | 2.125 | 1.750 | 1 1/4-11 1/2 | 1 1/4-11 1/2 | 4.631 | 4000 | 0.718 |

| 9 DP 24 MP 150 X FP 150 | 6.229 | 4.955 | 2.375 | 2.000 | 1 1/2-11 1/2 | 1 1/2-11 1/2 | 5.351 | 4000 | 0.844 |

|

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov |