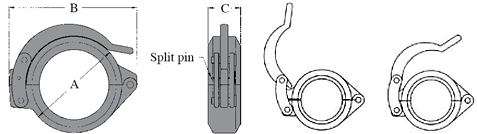

Series G28 Hinged Lever Coupling C-04

The Series G-28 Hinged Grooved Coupling is designed for quick connect and disconnect services. The housing segments are hinged with a lever handle for easy assembly. The use of the split pin can secure and prevent the accidental opening of the coupling. The Series G-28 can be used in a wide variety of applications with standard rolled or cut grooved pipe. Housings 1 1/2” - 4” (40 mm – 100 mm) feature a smooth outer surface, housings 5” - 12” (125 mm – 300 mm) feature a cross-ribbed design for added strength.

Standard gasket: Grade “E” EPDM or Grade “T” Nitrile.

Standard surface finish: Black electro-deposition coated.

| Nominal Size |

Pipe O.D. |

Max. Working Pressure (CWP)* |

ASME/ANSI Pressure Class Rating^ @100°F/@38°C |

Max. End Load (CWP) |

Axial Displacement † |

Angular

Movement / Deflection**† |

Dimensions |

Approx. Weight |

||

| A | B | C | ||||||||

| in | in | PSI | PSI | Lbs | in | Degrees (°) | in | in | in | Lbs |

| 1 1/2 | 1.9 | 300 | 300 | 850 | 0-0.06 | 1° - 54' | 2.95 | 4.65 | 1.85 | 2.2 |

| 2 | 2.375 | 300 | 300 | 1320 | 0-0.06 | 1° - 45' | 3.39 | 4.76 | 1.89 | 2.4 |

| 2 1/2 | 2.875 | 300 | 300 | 1940 | 0-0.06 | 1° - 15' | 3.62 | 5.91 | 1.89 | 3.1 |

| 76.1 mm | 3 | 300 | 300 | 2120 | 0-0.06 | 1° - 12' | 3.62 | 5.91 | 1 .89 | 3.1 |

| 3 | 3.5 | 300 | 300 | 2880 | 0-0.06 | 1° - 12' | 4.69 | 6.42 | 1 .89 | 4 |

| 4 | 4.5 | 300 | 300 | 4760 | 0-0.13 | 1° - 36' | 50 | 8.07 | 2.05 | 5.9 |

| 139.7 mm | 5.5 | 300 | 300 | 7120 | 0-0.13 | 1° - 18' | 44 | 9.96 | 2.05 | 10.8 |

| 5 | 5.563 | 300 | 300 | 7280 | 0-0.13 | 1° - 18' | 44 | 9.96 | 2.05 | 10.8 |

| 165.1 mm | 6.5 | 300 | 300 | 9950 | 0-0.13 | 1° - 07' | 8.39 | 10.94 | 2.05 | 13.2 |

| 6 | 6.625 | 300 | 300 | 10330 | 0-0.13 | 1° -05' | 8.50 | 11.06 | 2.05 | 13.2 |

| 8 | 8.625 | 300 | 300 | 17510 | 0-0.13 | 0° - 50' | 0.95 | 14.02 | 2.44 | 15.2 |

| 10 | 10.75 | 300 | 300 | 27210 | 0-0.13 | 0° - 40' | 3.50 | 17.80 | 2.52 | 36.1 |

* Working pressure is based on roll grooved standard wall carbon steel pipe.

^ The ASME/ANSI pressure class rating is not the design or maximum pressure rating, rather is provided for those that are accustomed to specifying or using ASME/ANSI pressure class rated components such as flange, valves, etc.

† Allowable Axial Displacement and Angular Movement (deflection) figures are for roll grooved standard steel pipe. Values for cut grooved pipe will be double that of roll grooved. These values are maximums; for design and installation purposes these figures should be reduced by: 50% for 3/4” – 3 1/2”; 25% for 4” and larger to compensate for jobsite conditions.

** Deflection or angular movement is the maximum value that a coupling allows under no internal pressure.

Performance Data

The following tables show the maximum working pressures (CWP) of Series G-28 Hinged Lever Coupling used on both carbon steel and stainless steel pipes. The ductile iron couplings can be used in conjunction with stainless steel pipe in non-corrosive environment as the flow media does not come in direct contact with the coupling housings but rather only the gasket.

| Series G-28 on Carbon Steel Pipe | |||||

| Nom. Size | Cut-Grooved | Roll-Grooved | |||

| in | XS | STD | STD | Sch. 10 | Sch. 7 |

| 1 1/2 | 300 | 300 | 300 | 300 | NR |

| 2 | 300 | 300 | 300 | 300 | NR |

| 2 1/2 | 300 | 300 | 300 | 300 | NR |

| 2 1/2 | 300 | 300 | 300 | 300 | NR |

| 3 | 300 | 300 | 300 | 300 | NR |

| 4 | 300 | 300 | 300 | 300 | NR |

| 5 | 300 | 300 | 300 | 300 | NR |

| 5 | 300 | 300 | 300 | 300 | NR |

| 6 | 300 | 300 | 300 | 300 | NR |

| 6 | 300 | 300 | 300 | 300 | NR |

| 8 | 300 | 300 | 300 | 250 | NR |

| 10 | 300 | 300 | 300 | 250 | NR |

| 12 | 300 | 300 | 300 | 250 | NR |

| Series G-28 on Stainless Steel Pipe | |||||

| Nom. Size | Cut-Grooved | Roll-Grooved | |||

| in / mm | Sch. 80S | Sch. 40S | Sch. 40S | Sch. 10S | Sch. 5S |

| 1 1/2 | 300 | 300 | 300 | 300 | NR |

| 2 | 300 | 300 | 300 | 300 | NR |

| 2 1/2 | 300 | 300 | 300 | 300 | NR |

| 2 1/2 | 300 | 300 | 300 | 300 | NR |

| 3 | 300 | 300 | 300 | 300 | NR |

| 4 | 300 | 300 | 300 | 175 | NR |

| 5 | 300 | 300 | 250 | 150 | NR |

| 5 |

300 |

300 |

250 |

150 |

NR |

| 6 | 300 | 300 | 250 | 150 | NR |

| 6 | 300 | 300 | 250 | 150 | NR |

| 8 | 300 | 300 | 200 | NR | NR |

| 10 | 300 | 300 | 200 | NR | NR |

| 12 | 300 | 300 | 200 | NR | NR |

Expansion Pipe

Lever handles are factory assembled pretty tight for safety sake. The use of an expansion pipe will be of help for an easy opening or closing.

| Expansion Pipe Size |

Applicable Coupling Sizes |

| 1/2” x 6” | 1 1/2" ~4" |

| 3/4” x 8” | 5" ~ 8" |

(You can easily make your expansion pipe simply by cutting sch. 401/2" or 3/4" pipe to a proper length)

Warning:

Lever handle couplings are not recommended for services where excessive shock-loads are present, as often occur in some concrete pumping applications. When the Series G-28 is used in concrete pumping applications, sound support and bracing practices should always be in effect. All couplings and components should be regularly inspected to ensure they are in good working condition and that the pipe grooves, coupling keys, and gasket are free of any concrete or foreign material.